FABRIC STRUCTURES

Fabric structures are not new: People have constructed tents since the earliest days of human civilization. During the last several decades, however, new, durable fabrics and computerized methods for Þ nding form and forces have helped to create a new construction type: a permanent, rigid, stable fabric structure that will last for 20 years or more.

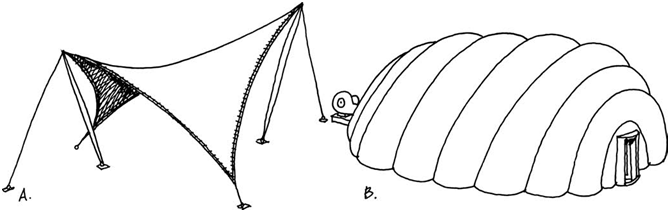

Fabric structures are either tensile or pneumatic (Figure A). A tensile fabric structure is a membrane supported by masts or other rigid structural elements such as frames or arches. The membrane usually consists of a woven textile fabric and is generally reinforced with steel cables along the main lines of stress. The fabric and cables transmit external loads to the rigid supports and ground anchors by means of tensile forces.

Pneumatic structures depend on air pressure for their stability and their capacity to carry snow and wind loads. The most common type of pneumatic structure is the airsupported structure, in which an airtight fabric, usually reinforced with steel cables, is held up by pressurizing the air in the inhabited space below it. The fabric and cables in an air-supported structure are stressed in tension.

fabrics for permanent structures

Nearly all fabric structures are made of woven cloth that has been coated with a synthetic material. The cloth provides structural strength to resist the tensile forces in the structure, and the coating makes the fabric airtight and water resistant. The most widely used fabric is polyester cloth that has been laminated or coated with polyvinylchloride (vinyl, PVC). Two other frequently used, longerlasting fabrics are based on glass Þ ber cloth: One is coated with polytetraß uorethylene (PTFE, the most common brand of which is known as Teß on); the other is coated with silicone. The polyester/PVC fabric is the most economical of the three, but it does not meet U.S. building code requirements for a noncombustible material and is used predominantly for smaller structures. The glass/ PTFE and glass/silicone fabrics are classiÞ ed as noncombustible. Though it is more expensive, the glass/PTFE fabric remains clean longer than the other two. All three fabrics are highly resistant to such forces of deterioration as ultraviolet light, oxidation, and fungi.

Fabrics may be white, colored, or imprinted with patterns or graphics. A fabric may be totally opaque, obstructing all passage of light, or it may be translucent, allowing a controlled percentage of light to pass through.

Though a single layer of fabric has little resistance to the ß ow of heat, a properly designed fabric structure can achieve substantial energy savings over conventional enclosures through selective use of translucency and reß ectivity. Translucency can be used to provide natural illumination, gather solar heat in the winter, and cool the space at night in the summer. A highly reß ective fabric can reduce solar heat gain and conser ve artiÞ cial illumination. With the addition of a second layer, a fabric liner that is suspended about a foot (300 mm) below the structural fabric, the thermal resistance of the structure can be improved. An acoustic inner liner can help to control internal sound reß ection, which is especially important in air-supported structures, which tend to focus sound. Tensile structures, because of their anticlastic cur vature, tend to disperse sound rather than focus it.

Figure A

Simple tensile and pneumatic (air-supported) fabric structures. (Sketch by Edward Allen)

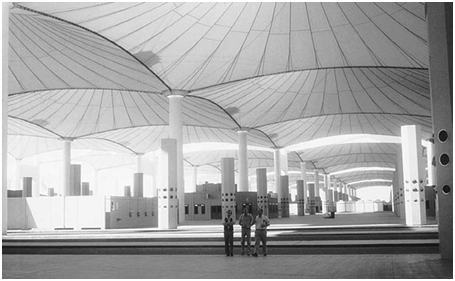

Figure B

The world's largest roof structure covers the Haj Terminal in Jeddah, Saudi Arabia,

a colossal airport facility that is used to facilitate the travel of vast numbers of

Muslim faithful during a short period of annual pilgrimage. The roof is made up of

radial shapes. (Architects: Skidmore, Owings & Merrill.

Roof designer and structural engineer:

Geiger Berger Associates. Photographs for Figures B–G are furnished by the courtesy of thephotographer, Horst Berger.)

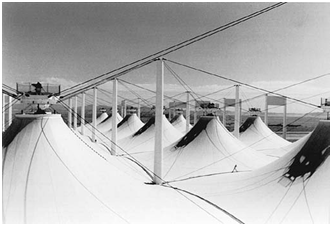

Figure C

The fabric of the Haj Terminal is PTFE coated glass fiber cloth.

We have a large enquiry for PTFE fabric for iconic structure in Saudi Arabia. We invite you for quotation of Design, supply of drawing , fabrication and erection as separate rate. Please send us you email ID so that we can forward you the basic drawing for your reference.

Thanks