Light gauge steel construction is the noncombustible equivalent of wood light frame construction. The external dimensions of the standard sizes of light gauge members correspond closely to the dimensions of the standard sizes of nominal 2-inch (38-mm) framing lumber. These steel members are used in framing as closely spaced studs, joists, and rafters in much the same way as wood light frame members are used, and a light gauge steel

frame building may be sheathed, insulated, wired, and Þ nished inside and out in the same manner as a wood light frame building.

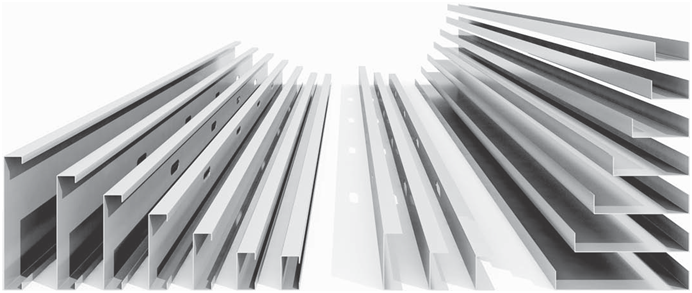

The steel used in light gauge members is manufactured to ASTM standard A1003 and is metalliccoated with zinc or aluminum-zinc alloy to provide long-term protection against corrosion. The thickness of the metallic coating can be varied, depending on the severity of the environment in which the members will be placed. For studs, joists, and rafters, the steel is formed into C-shaped cee sections (Figure 12.1). The webs of cee members are punched at the factory to provide holes at 2-foot (600mm) intervals; these are designed to allow wiring, piping, and bracing to pass through studs and joists without the necessity of drilling holes on the construction site. For top and bottom wall plates and for joist headers, channel sections are used. The strength and stiffness of a member depend on the shape and depth of the section and the gauge (thickness) of the steel sheet from which it is made. A standard range of depths and gauges is available from each manufacturer. Commonly used metal thicknesses for loadbearing members range from

0.097 to 0.033 inch (2.46Ð 0.84 mm) and are as thin as 0.018 inch (0.45 mm) for nonloadbearing members.

At least one manufacturer produces nonloadbearing light gauge steel members by passing steel sheet through rollers with mated patterned surfaces, producing a dense array of dimples in the metal of the formed members. The additional cold working of the metal that occurs during the forming process and the Þ nished

Figure 12.1

Typical light gauge steel framing members.

To the left are the common sizes of cee studs and joists. In the center are channel studs. To the right are runner channels.