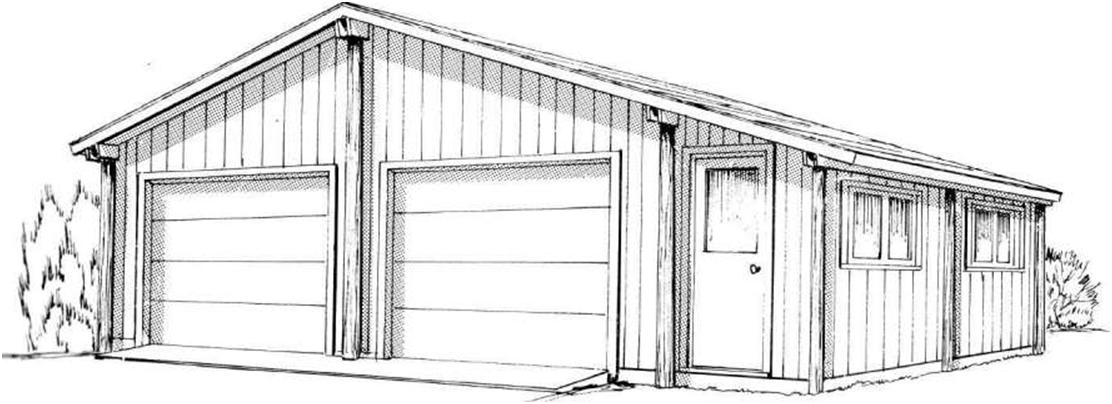

A choice of layouts and of roof line is possible in the construction of this building simply by moving the tool shed from the rear to either side, and by switching the location of the poles to match. In this case the distance between the poles from front to back would be 11 feet and from side to side 121/2 feet.

This choice will be determined by how best the building fits on your lot, its relation to driveway and house. Note also that in the alternate version rain will drain to the sides of the building. Where the roof slopes toward the doors, a rain gutter would be indicated*. In this plan the building is 28 V2 feet long and 25 feet wide.

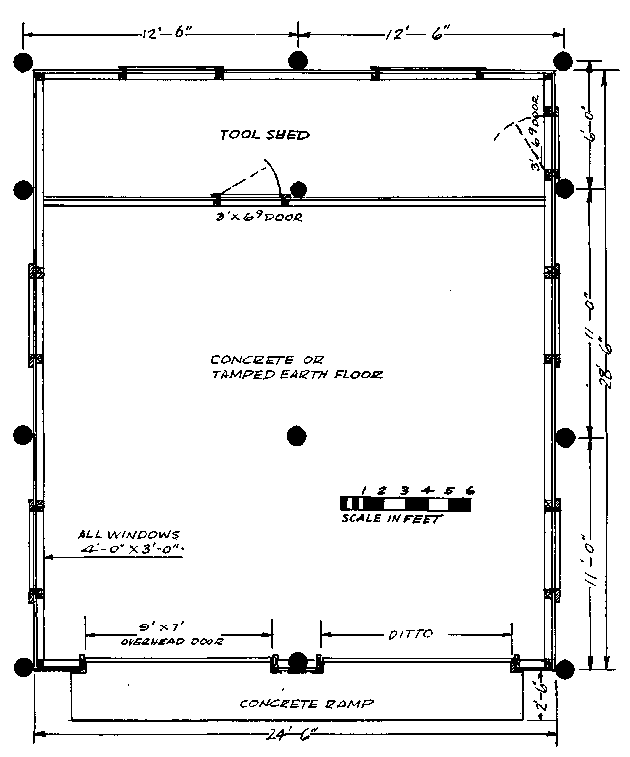

Farm and country residents may wish to modify the dimensions of this building to accommodate trucks, tractors and other vehicles which require more vertical and lateral clearance than the specified 9 x 7-foot door openings, which are standard garage door dimensions. Larger overhead garage doors are available from building suppliers, though usually only on special order.

Simple modifications of these plans can be worked out to “stretch” the building both vertically and horizontally in proportions which will not materially alter the one-to-four pitch of the roof. A close calculation should be made in planning any such modifications, however, to determine the increased length needed for poles, planks, boards and sheathing to keep the needs consistent with standard lumber lengths. Bear in mind also that a lesser roof pitch might cause serious problems in snow country, while a steeper pitch might destroy the visual harmony of the building’s proportions.

Prior to the start of construction of the building, additional plans should be made if there will be a need for heat in the tool shed part or the whole structure.

Except in very severe climate conditions a limited heat supply in the toolshed area may be sufficient for most needs, if that room is to contain also a workbench area. Simple insulation of the toolshed walls and roof then is indicated, as well as provision for a small space heater with roof chimney located at the blind end of the shed.

In most cases electricity for lights and power tools will be important. If the building is located near the home the wiring can be brought in by underground conduit and connected (on a new circuit) to the home’s central circuit box. Make a determination ahead if there is a possibility that 220-volt service will be needed in the garage for electric heating or other heavy appliances. Otherwise the service wiring should be chosen to carry the maximum anticipated use load in the building.

It is unlikely that a water supply will be required in the garage, particularly if the building is adjacent to the home and a house sillcock is located within 50 feet. Drainage of the garage floor area may prove extremely important, however, and provisions should be made if a concrete floor is poured.

Though requiring considerable care in grading, a slab that slopes gently to a drain in its center will be the best plan because it keeps water dripping from the garaged vehicles

|

||

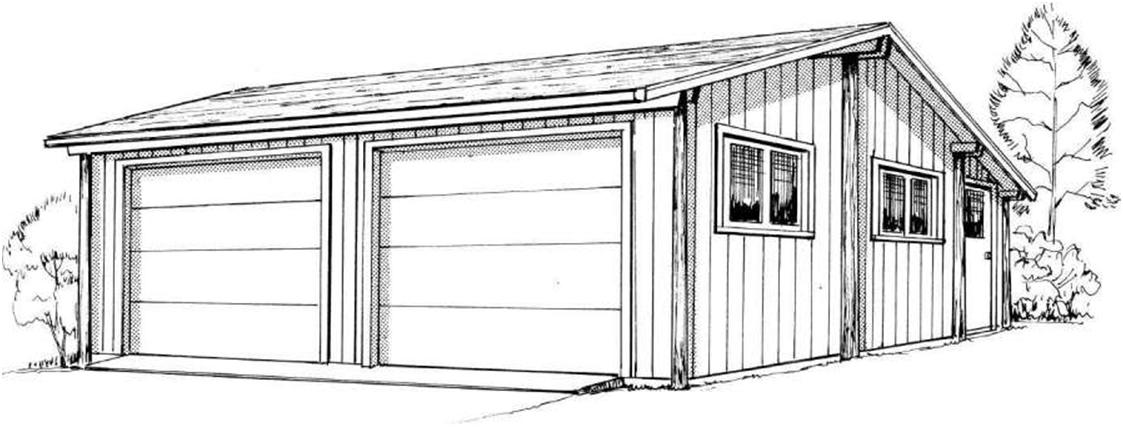

| Garage with tool shed located at rear. Siding is textured plywood or tongue and groove boards. | ||

| Alternate Arrangement of Garage locates the tool shied to the right or left of the garage doors Instead of In the back. | ||

|

||

|

GARAGE FLOOR PLAN Builder may decide to include a hard-surfaced floor, as discussed on Page 67. |

||

|

away from the building’s exterior wood. Standard iron drain tiles with grill covers are available from most building supply firms. Cement floors are prone to cracking in areas where the winters are severe, if subsoil drainage is not good and the gravel pad is not adequate. For this reason, and that it may be cheaper in some areas, a heavy blacktop floor may be a better choice, although it involves the installation by a professional paving firm. A packed earth floor may be perfectly satisfactory, however, in climates where rain and snow are not excessive. A cement or asphalt garage floor could be added later if the earth floor proves a deterrent. It will be more difficult to do it once the building is completed, however, and the earth cover would have to be removed first from its gravel base. |

||

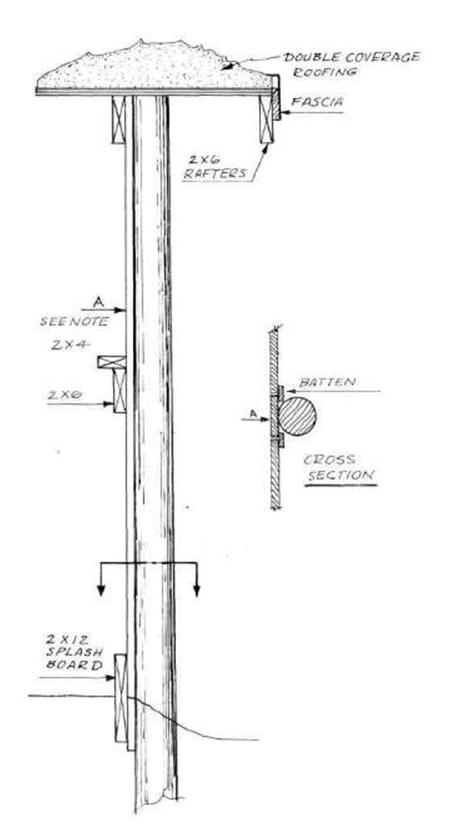

| FACING THE POLES When erecting the outside poles, nail to them vertically on the inside faces, boards about the same width as the pole diameter. These will help in truing the poles vertically and also will provide the proper clearance between poles, splash board, plates and girts for the siding. |

|||

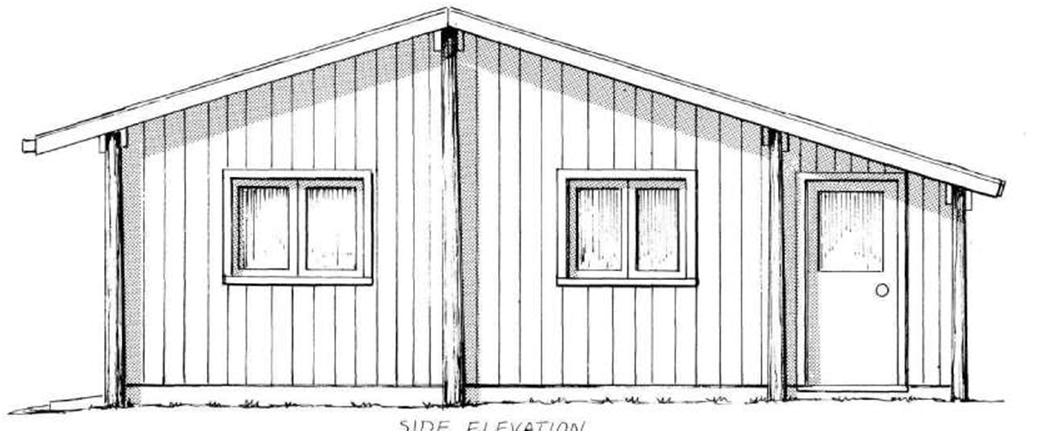

| SIDE VIEW OF GARAGE The tool shed, located at the back in this plan, has i t s own access door. |

||

|

||

|

||

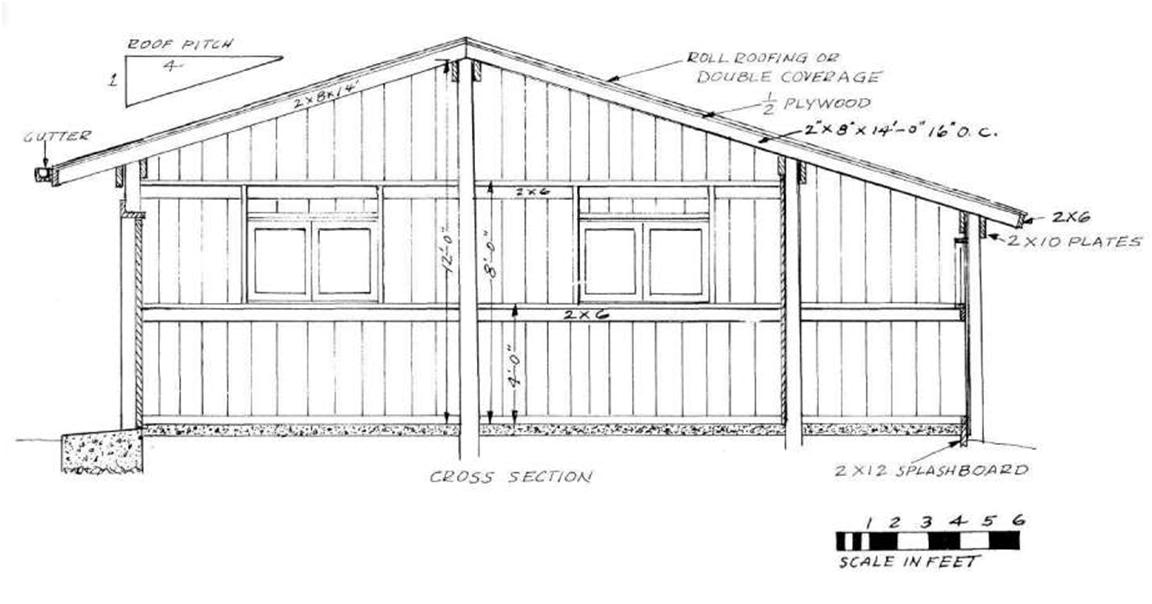

| GARAGE CROSS-SECTION This roof is designed to safely carry a snow load of 40 pounds per square foot. |

||

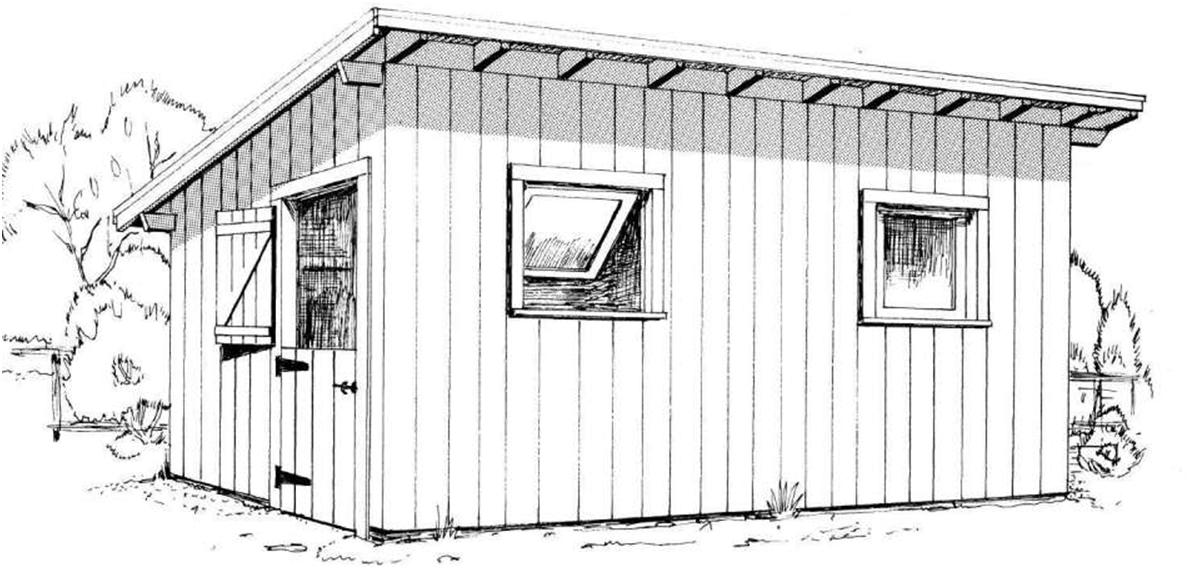

| STORAGE S H E D | ||

| In some applications this simple 7-pole building could double as housing for small animals or poultry. | ||

|

||