Standard wide-ß angle beams are suitable for the range of structural spans normally encountered in of ces, schools, hospitals, apartment buildings hotels, retail stores, warehouses, and other buildings in which columns may be brought to earth at intervals without obstructing the activities that take place within. For many other types of buildings non athletic buildings, certain types of industrial buildings, aircraft hangars, auditoriums, theaters, religious buildings, transportation terminals longer spans are required than can be accomplished with wide-ß angle beams. A rich assortment of longer-span structural devices is available in steel for these uses.

Improved Beams

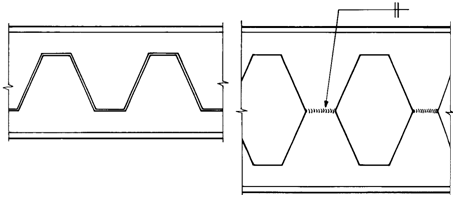

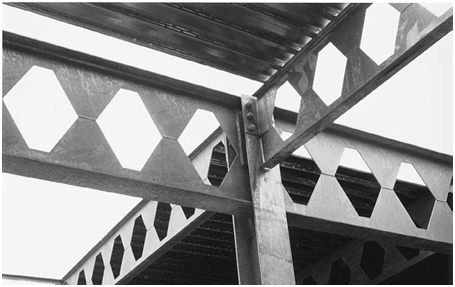

One general class of longer-span devices might be called improved beams. The castellated beam (Figures 11.77 and 11.78) is produced by ß angle cutting the web of a wide-ß angle section along a zigzag path, then reassembling the beam by welding its two halves point to point, thus increasing its depth without increasing its weight. This greatly augments the spanning potential of the beam, provided that the superimposed loads are not exceptionally heavy.

For long-span beams tailored to any loading condition, plate girders are custom designed and fabricated. Steel plates and angles are assembled by bolting or welding in such a way as to put the steel exactly where it is needed: The ß anges are often made thicker in the middle of the span where bending forces are higher, more web stiffeners are provided near the ends where web stresses are high, and areas around the supports are specially reinforced. Almost any depth can be manufactured as needed, and ver y long spans are possible, even under heavy loads (Figure 11.79). These members are often tapered, having greater depth where the bending moment is largest.

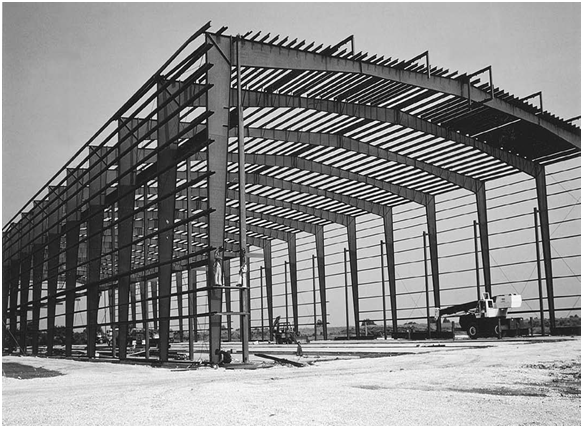

Rigid steel frames are efficiently produced by welding together steel wide ß angle sections or plate girders. They may be set up in a row to roof a rectangular space (Figure 11.80) or arrayed around a vertical axis to cover a circular area. Their structural action lies midway between that of a rectilinear frame and that of an arch. Like an arch, they may sometimes require steel tie rods at the base to resist lateral thrust, in which case these rods are usually concealed within the ß door slab.

Castellated beams, plate girders, and rigid steel frames share the characteristic that because they are long, slender elements, they frequently must be braced laterally by purlins, girts, decking, or diagonal bracing to prevent them from buckling.

|

Figure 11.77 Manufacture of a castellated beam. |

|

Figure 11.78 Castellated beams and girders frame into a wide-flange column. (Courtesy of Castelite Steel Products, Midlothian, Texas) |

|

Figure 11.79 Erecting a welded steel plate girder. Notice how the girder is custom made with cutouts for the passage of pipes and ductwork. The section being erected is 115 feet (35 m) long, 13 feet (4 m) deep, and weighs 192,000 pounds (87,000 kg). (Courtesy of Bethlehem Steel Corporation) |

|

Figure 11.80 The steel rigid frames of this industrial building carry steel purlins that will support the roof deck and girts to support the wall cladding. The depth of each frame varies with the magnitude of the bending forces and is greatest at the eave connections, where these forces are at

|