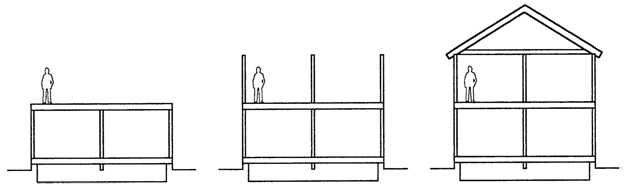

| Although complex in its details, the platform frame is simple in concept (Figure 5.3). A ß oor platform is built. Loadbearing walls are erected upon it. A second-ß oor platform is built upon these walls and a second set of walls upon this platform. The attic and roof are then built upon the second set of walls. There are, of course, many variations: A concrete slab that lies directly on the ground is sometimes substituted for the ground-ß oor platform; a building may be one or three stories tall instead of two; and several types of roofs are frequently built that do not incorporate attics. The essentials, however, remain: A ß oor platform is completed at each level, and the walls bear upon the platform rather than directly upon the walls of the story below. The advantages of the platform frame over the balloon frame are several: It uses short, easily handled |

lengths of lumber for the wall framing. Its vertical hollow spaces are automatically restopped by the platform framing at each ß oor. Its platforms are convenient working surfaces for the carpenters who build the frame. The major disadvantage of the platform frame is that each platform constitutes a thick layer of wood whose grain runs horizontally. This leads inevitably to a relatively large amount of vertical shrinkage in the frame as excess moisture dries from the wood, which can cause distress in the exterior and interior nish surfaces. A conventional platform frame is made entirely of nominal 2-inch members, which are actually 1½ inches (38 mm) in thickness. These are ordered and delivered cut to the nearest 2-foot (600-mm) length, then measured and sawn to exact length on the building site. All connections are made with nails, using either face nailing, end nailing, or toe nailing (Figure 3.39) as required by the characteristics of each joint. Nails are driven either by hammer or nail gun. In either case, the connection is quickly made because the nails are installed without drilling holes or otherwise preparing the joint. Each plane of structure in a platform frame is made by aligning a number of pieces of framing lumber parallel to one another at speciÞ ed intervals, nailing these to |

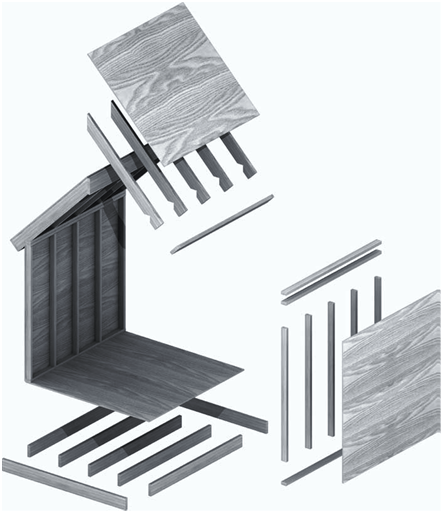

crosspieces at either end to maintaintheir spacing and ß atness, and then covering the plane of framing with sheathing, a facing layer of boards or panels that join and stabilize the pieces into a single structural unit, ready for the application of nish materials inside and out (Figure 5.4). In a ß oor structure, the parallel pieces are the ß oor joists, and the crosspieces at the ends of the joists are called headers, rim joists, or band joists. The sheathing on a ß oor is known as the subfl oor. In a wall structure, the parallel pieces are the studs, the crosspiece at the bottom of the wall is the sole plate or bottom plate, and the crosspiece at the top (which is doubled for strength if the wall bears a load from above) is called the top plate. In a sloping roof, the rafters are headed off by the top plates at the lower edge of the roof and by the ridge board at the peak. Openings are required in all these planes of structure: for windows and doors in the walls; for stairs and chimneys in the ß oors; and for chimneys, skylights, and dormers in the roofs. In each case, these are made by heading off the opening: Openings in ß oors are framed with headers and trimmers (Figure 5.17), which usually must be doubled to support the higher loads placed on them by the presence of the opening. In walls, sills head off the bottoms of window and door openings, while trimmer studs on the sides provide support to |

Figure 5.3

The concept of platform framing, shown in cross section, reading from left to right: A foundation

wall is constructed. A ground-fl oor platform is framed and sheathed. Ground-fl oor wall frames

are assembled horizontally on the platform, then tilted into their fi nal positions. A second-fl oor

platform is constructed on top of the ground-fl oor walls, and the process of wall construction is

repeated. The attic fl oor and roof are added.

|

Figure 5.4 The basic components of platform frame construction. (a) Walls are framed with repetitive vertical studs that are connected at the top and bottom by horizontal plates. (b) Floors are framed with repetitive joists that are connected at their ends by headers. (c) Roofs are framed with rafters. Every surface is sheathed with wood panels of either plywood (as shown) or, more commonly, less expensive OSB.

|